All Categories

Product Details

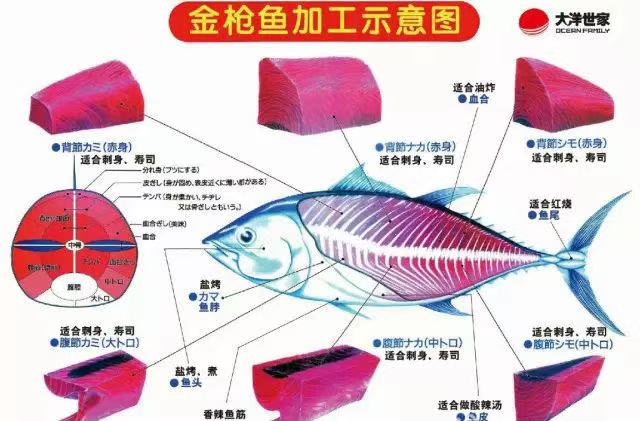

- Otoro: Located in the lower abdomen at the very front of the fish, it is the part of the tuna with the highest fat content, with soft, melt-in-your-mouth meat that has a rich, mellow flavor and is the most expensive. Its fat has a clear texture and a beautiful marbling pattern, making it a top ingredient for sashimi and sushi in Japanese cuisine.

- Midriff (Chutoro): It is located in the lower part of the middle of the fish body, with moderate fat content, and has a texture that combines the softness of the large belly and the chewiness of the naked body, with a balanced flavor and a relatively affordable price. It has a certain aroma of fat and the texture of the tuna itself, making it a popular part of the fish, and is common in sashimi, sushi, and some Japanese cuisine.

- Akami: Distributed on the back of the fish, it is low in fat, dark red in color, rich in protein, and has a refreshing and chewy flavor with a hint of tuna's unique flavor. Akame is relatively low in price, and is commonly used in various Japanese dishes, such as tuna over rice, and is also often used in canned goods, retaining the original meaty texture of tuna.

- Kama Toro (cheek meat): Located near the gills of the tuna, it is scarce, firm and rich in fat, has a unique flavor and aroma when cooked, and is often used in grilling to maximize its flavor.